Industrial facilities may not always make the headlines, but they’re the silent powerhouses keeping the world moving. Every product you buy, every shipment that arrives, and every technology that reaches your hands has passed through the veins of these operations.

They are the true backbone of global supply chains — and without them, modern commerce would collapse overnight.

Let’s break down why these spaces matter so much, how they’re evolving, and what makes them the beating heart of global logistics.

Industrial facilities form the backbone of global supply chains by powering production, logistics, and innovation across industries. They enable seamless material flow, support billions in global trade, and evolve through automation, AI, and sustainability initiatives. From manufacturing precision to energy efficiency, these facilities are where physical goods meet digital intelligence — keeping economies resilient, adaptable, and ready for the future of global commerce.

The Invisible Machinery Behind Everyday Life

When we think about how things get made, we often picture factories filled with machines or workers assembling products. But the truth is, industrial facilities are much more than that — they are massive ecosystems that connect suppliers, manufacturers, distributors, and retailers in a seamless loop.

A single delay in an industrial facility can ripple across the entire planet. Remember the Suez Canal blockage in 2021? A few days of disruption caused billions in losses and shortages everywhere. That’s the kind of leverage these facilities have in today’s interconnected economy.

Industrial facilities function like central nervous systems — collecting, storing, and distributing materials through automated precision. From automotive plants in Germany to semiconductor clean rooms in Taiwan, these hubs ensure that global trade keeps humming.

The Scale and Complexity of Industrial Operations

Most people underestimate the scale of operations inside industrial facilities. We’re not talking about a few machines on a shop floor — we’re talking about vast infrastructures spanning hundreds of thousands of square meters.

Each section has a dedicated purpose: production, quality control, logistics, safety, energy management, and more. Every light, conveyor belt, and robotic arm is part of a finely tuned orchestra.

Modern industrial facilities are also data-driven. Every piece of equipment is monitored by sensors, creating a digital ecosystem where efficiency, waste, and output are measured in real time.

It’s not just about producing things anymore — it’s about producing intelligently.

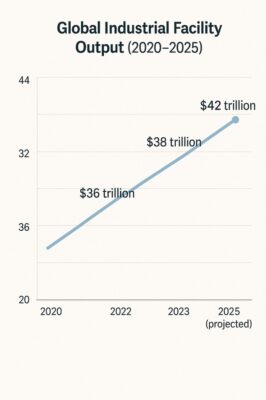

This chart would show how global industrial facilities are expanding their influence as economies grow more dependent on production networks.

Why Industrial Facilities Are Irreplaceable

You might ask — can’t advanced digital systems or AI replace physical industrial facilities? The answer is simple: absolutely not.

Even as automation, AI, and robotics reshape production, physical infrastructure remains essential. You can automate decision-making, but you can’t 3D print a warehouse or cloud-store raw materials.

The physical movement of goods is still at the core of every industry — from tech to textiles.

Industrial facilities provide three things that digital systems cannot:

- Physical capacity — the space and infrastructure to produce, package, and ship.

- Scalability — the ability to grow production based on demand.

- Control — monitoring quality, safety, and timing with precision.

Without these three pillars, even the most advanced digital systems would fail to deliver consistent results.

The Role of Industrial Facilities in the Supply Chain Loop

Every supply chain has key phases — sourcing, production, distribution, and delivery. Industrial facilities sit at the core of all four.

They’re where raw materials are transformed into components, where those components become final products, and where products are prepped for shipment. In some cases, they even handle returns and recycling.

Think of them as multi-layered logistics brains.

When one industrial facility goes offline — due to weather, political conflict, or maintenance — the chain breaks. The global nature of supply networks means that a delay in one region impacts another within hours.

That’s why redundancy and diversification are now critical — companies invest in multiple industrial facilities across continents to avoid single points of failure.

Automation and the Smart Facility Revolution

The rise of “smart factories” is changing everything.

With the Internet of Things (IoT), sensors, and AI-driven analytics, industrial facilities are becoming intelligent ecosystems. Machines communicate with each other, predictive maintenance prevents downtime, and data analysis enhances performance continuously.

This doesn’t just boost productivity — it redefines precision.

Imagine a facility that predicts when a conveyor belt will fail before it happens or adjusts production speeds based on weather conditions affecting global shipping routes.

That’s not science fiction. It’s happening today.

Automation and smart monitoring are cutting energy costs, reducing waste, and speeding up output — all while maintaining safety and sustainability standards.

Sustainability and the Green Shift

Here’s a surprising fact: industrial facilities consume around 54% of global energy and produce over one-third of global CO₂ emissions.

That’s a big problem — but also a massive opportunity.

The world’s shift toward sustainability means these facilities are now under pressure to go green — integrating renewable energy, circular waste systems, and energy-efficient technologies.

Solar-powered production lines, closed-loop water systems, and zero-emission logistics centers are becoming the new standard.

Some industrial facilities are even redesigning their layouts to optimize airflow, lighting, and temperature control, reducing operational costs while cutting emissions.

The green revolution isn’t just about ethics — it’s about long-term profitability and global competitiveness.

Industrial Facilities and Global Employment

Beyond machines and metrics, there’s a human side to this story.

Industrial facilities employ hundreds of millions of people worldwide — technicians, engineers, quality inspectors, safety experts, and logistics coordinators.

They are also centers of skill evolution. As automation grows, workers transition from manual labor to technical roles, managing systems rather than operating them.

The new generation of industrial workers is digitally fluent, sustainability-minded, and globally connected.

That human adaptability keeps the supply chain not just alive — but evolving.

The Future of Industrial Facilities

Looking ahead, industrial facilities will become even more integrated with digital ecosystems.

Expect to see:

- AI-driven logistics predicting global disruptions.

- Blockchain-based tracking ensuring supply transparency.

- Digital twins simulating operations before physical changes.

- Robotic swarms managing micro-tasks with millimeter precision.

But despite the technology, the principle remains the same: industrial facilities will always be the backbone of production and trade.

The world may digitize further, but physical reality still runs the show — and industrial facilities are where that reality is built, tested, and shipped.

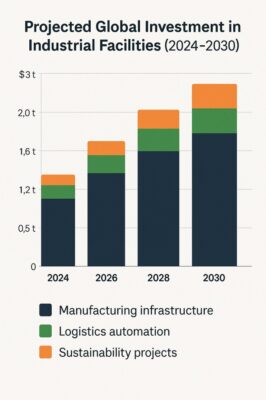

This chart visually underscores the immense global confidence in industrial facilities as long-term assets for stability and innovation.

Conclusion

Without industrial facilities, the global economy would grind to a halt.They are not just spaces filled with machines — they are living, breathing networks of innovation, human expertise, and logistical precision.

They form the foundation upon which global supply chains rest, adapt, and grow. As technology evolves and sustainability reshapes business priorities, one truth remains constant: industrial facilities are the backbone of progress — and the future still runs through them.

Andrea Balint is a writer and researcher focused on human behavior, workplace psychology, and personal growth. Through her work at CareersMomentum, she explores how mindset, leadership, and emotional intelligence shape modern careers. With a background in communication and HR development, she transforms complex ideas into practical insights that help readers build clarity, confidence, and professional purpose.