In today’s fast-paced business environment, the pressure to do more with less is stronger than ever. From startups to global enterprises, companies are constantly seeking cost savings—not just to improve the bottom line but to maintain a competitive edge. However, the challenge lies in achieving those savings without sacrificing the quality that customers, employees, and stakeholders expect.

Too often, the conversation around cost savings is framed in terms of cutbacks, layoffs, or diminished service. But cost-conscious strategies don’t have to mean corner-cutting. In fact, the most successful businesses are those that view cost savings not as a desperate necessity, but as a strategic opportunity to refine operations, embrace innovation, and enhance value.

Table of Contents

- The Myth of the Quality-Cost Trade-Off

- Value Engineering: A Smarter Approach

- Technology as a Cost Savings Catalyst

- The Human Element: Training, Not Trimming

- Procurement and Vendor Optimization

- Avoiding False Economies

- Data-Driven Decisions for Sustainable Results

- Communication and Transparency

- Building a Culture of Smart Spending

- Conclusion: Excellence Doesn’t Have to Be Expensive

The Myth of the Quality-Cost Trade-Off

Let’s begin by debunking a persistent and damaging myth: that reducing costs inevitably results in a decline in quality. This outdated belief stems from experiences in which cost-cutting was reactive—done hastily, without strategy, and often at the expense of customer satisfaction or operational integrity. But forward-thinking organizations understand a deeper truth. With the right systems, mindset, and innovation, meaningful savings can be achieved without sacrificing performance.

In fact, quality and cost efficiency are no longer at odds. They’re becoming complementary goals, especially as industries embrace smarter tools and streamlined workflows. One of the best illustrations of this shift is seen in call center cost savings strategies that not only reduce expenses but also improve service delivery.

Operational Efficiency That Elevates Quality

Consider the manufacturing sector. Many leading companies have implemented lean production methodologies—focused on eliminating waste, reducing downtime, and optimizing every step of the process. These aren’t just budget-conscious decisions; they’re quality-conscious too. When processes are streamlined, defects decrease and consistency improves. In this context, cost savings and quality enhancement go hand in hand.

This same principle applies to service industries, particularly customer support. Modern businesses are leveraging automation, cloud solutions, and AI-powered platforms to create call center cost savings that are both substantial and sustainable. But what’s striking is that these savings often come with an improvement in response time, accuracy, and customer satisfaction.

Call Centers: A Case Study in Intelligent Cost Reduction

In the world of customer service, call center cost savings have become a strategic priority—but not at the expense of quality. Businesses are increasingly adopting AI-driven virtual assistants and chatbots that handle high-volume, low-complexity interactions. This shift reduces the need for large human teams while freeing up experienced agents to handle more complex and emotionally nuanced cases.

The result? A more cost-effective operation and a better customer experience. By routing calls intelligently and ensuring customers are matched with the right resources, call centers can decrease average handle times and increase first-call resolution—two critical metrics that directly impact both costs and satisfaction.

Technology as a Catalyst for Savings and Quality

Cloud-based contact center platforms are another powerful enabler of call center cost savings. These platforms reduce overhead associated with physical infrastructure, enable remote work (which broadens the talent pool), and support real-time analytics that guide performance improvements.

AI isn’t just for automation either—it can be used to analyze sentiment, predict call outcomes, and personalize responses based on caller history. This level of service was once prohibitively expensive. Now, it’s becoming standard, and the cost to deliver it is shrinking.

When organizations harness these technologies, they unlock call center cost savings while actually strengthening their quality of service. It’s a win-win—made possible by strategic foresight and digital transformation.

Beyond the Call Center: A Universal Principle

The insight gained from call center cost savings efforts extends far beyond the support desk. It illustrates a broader principle: cost savings should be a byproduct of smart design, not a forced compromise. The most successful organizations today bake efficiency into the foundation of their operations. They ask, “How can we do this better, faster, and with less?”—without ever lowering their standards.

In healthcare, for example, electronic records reduce administrative costs while improving patient outcomes. In logistics, route optimization cuts fuel costs and shortens delivery times. In education, adaptive learning platforms reduce the need for in-person tutoring while improving comprehension rates. The pattern is clear: smart cost reduction is aligned with, not opposed to, quality.

Reframing the Conversation Around Cost

It’s time to shift the narrative. Instead of asking whether cost savings will hurt quality, we should be asking: What changes will allow us to reduce costs and improve outcomes at the same time? That’s the question being answered every day in call centers, factories, hospitals, and boardrooms.

The idea that you must sacrifice quality to save money is not just outdated—it’s a barrier to innovation. From intelligent automation to process redesign, modern strategies are proving that call center cost savings and exceptional service can coexist. And if it works in call centers, it can work just about anywhere.

The Future Is Cost-Effective and High-Quality

As digital tools become more accessible and organizations continue reimagining how they operate, we’ll see more examples of cost and quality advancing together. Leaders who prioritize call center cost savings while enhancing customer experience are laying a blueprint for others to follow.

In the end, it’s not about cutting corners—it’s about cutting waste. And when that’s the mindset, everyone wins: the business, the employees, and most importantly, the customers.

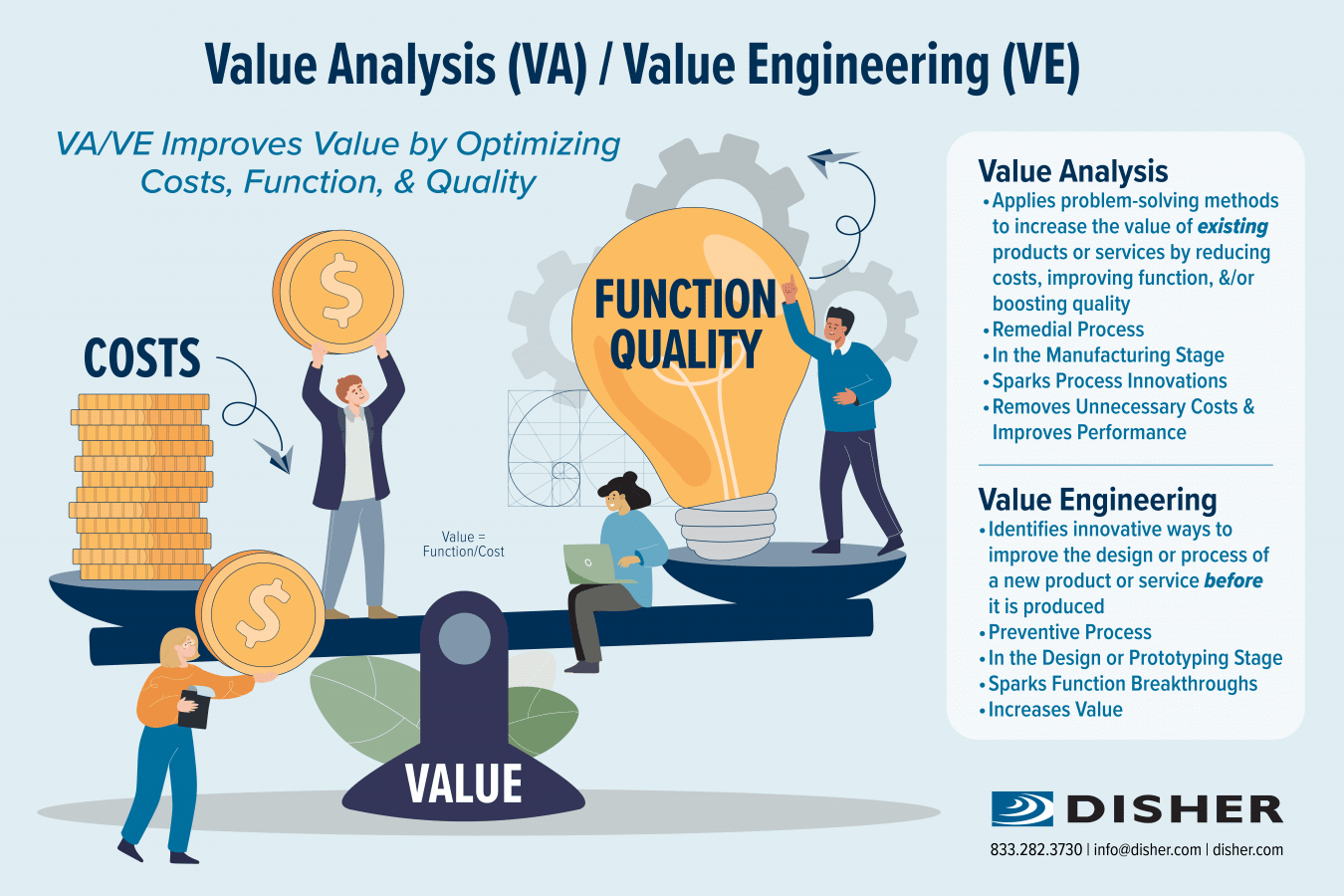

Value Engineering: A Smarter Approach

One of the best ways to strike the balance between quality and cost savings is through value engineering. This isn’t about slashing features or downgrading materials; it’s about understanding what matters most to your customer and aligning your product or service to those priorities. By revisiting your design, supply chain, or delivery model with fresh eyes, you can often eliminate unnecessary expenses without undermining performance.

This might mean switching to more sustainable packaging that costs less and improves brand image. It could involve standardizing components across product lines to increase purchasing power and simplify inventory. Or it may require reimagining workflows to better use your team’s time and talents. The end goal is the same: smarter spending, not simply spending less.

Technology as a Cost Savings Catalyst

Digital transformation is another major driver of cost savings—and one that doesn’t ask you to compromise on quality. Cloud computing, for instance, allows companies to scale infrastructure dynamically without overpaying for unused capacity. AI tools can analyze customer behavior to reduce churn or improve targeting, improving ROI without ballooning ad budgets.

Software-as-a-Service (SaaS) tools have also revolutionized how businesses operate. With monthly subscriptions replacing expensive licenses, companies now enjoy access to world-class tools with flexible costs. Automation reduces human error, shortens cycle times, and frees up talent for higher-value tasks. The net result? Sustainable cost savings and higher productivity.

The Human Element: Training, Not Trimming

When businesses seek to tighten budgets, human resources are often the first area targeted. Layoffs, hiring freezes, and departmental cuts are treated as shortcuts to financial relief. But in reality, reducing headcount rarely results in sustainable gains. In fact, such strategies often lead to diminished morale, lowered productivity, and increased turnover—all of which undercut long-term goals. Instead, forward-thinking companies are embracing a different path to efficiency: training and development.

Why Human Capital Is Central to Procurement Cost Savings

It’s tempting to believe that the biggest opportunities for procurement cost savings lie in renegotiating supplier contracts or optimizing inventory. While those tactics have merit, many hidden inefficiencies stem from a workforce that lacks the skills or autonomy to spot and solve problems. Employees who are trained to think critically and act decisively can uncover waste, improve workflows, and boost quality—all of which translate directly into procurement-related savings.

In other words, procurement cost savings don’t just emerge from spreadsheets—they emerge from smart, empowered people.

Training Pays Off in More Ways Than One

Consider the ripple effects of training a customer service team on advanced issue resolution or conflict management. Not only does it increase customer satisfaction, but it also reduces the number of repeat calls, returns, and complaints. That’s less resource drain, fewer escalations, and more loyal customers. These improvements contribute to procurement efficiency by preventing unnecessary replacements, refunds, or service calls.

And because these effects are scalable, even a small investment in upskilling can create disproportionately large procurement cost savings over time.

Cross-Functional Skills Create Agile Teams

Another overlooked benefit of training is increased agility. When employees understand multiple facets of the business, they can shift roles, adapt faster, and work collaboratively across silos. For example, a marketing team trained in basic procurement processes can plan campaigns more strategically, minimizing last-minute orders or rushed vendor requests—two common sources of budget overrun.

This kind of cross-functional awareness doesn’t just break down inefficiencies—it actively supports smarter purchasing and long-term procurement cost savings.

Avoiding the Hidden Costs of Undertrained Teams

When employees lack the proper training, mistakes happen. Miscommunications with vendors, poorly written RFPs, and botched logistics can all lead to expensive errors. These aren’t just operational hiccups; they erode trust with suppliers and drive up indirect costs. Investing in targeted training mitigates these risks by equipping teams with the tools and context they need to avoid missteps in the first place.

Avoiding these errors is one of the most reliable—yet often invisible—ways to achieve procurement cost savings.

Retention as a Strategic Financial Win

Turnover is expensive. Recruiting, onboarding, and training new employees takes time and money, not to mention the institutional knowledge lost when seasoned staff walk out the door. When companies invest in their employees’ growth, they send a clear signal: you’re valued. This creates loyalty, lowers attrition, and preserves operational continuity.

The result? Lower HR costs and more consistent procurement practices—two factors that directly influence long-term procurement cost savings.

Empowered Employees Drive Innovation in Procurement

Procurement isn’t just about buying smarter—it’s about thinking smarter. Employees who are engaged and well-trained are more likely to suggest process improvements, identify bulk-buying opportunities, or catch redundancies in vendor contracts. These proactive contributions often go unmeasured, but they play a vital role in compounding procurement cost savings across the organization.

Innovation doesn’t come from cutting people—it comes from enabling them.

Procurement and Vendor Optimization

Another major area ripe for cost savings is vendor and procurement management. Too many businesses fall into “set it and forget it” mode with suppliers, missing out on negotiation opportunities, better terms, or alternative solutions. Strategic sourcing practices—such as consolidating vendors, renegotiating contracts, or introducing competitive bidding—can yield significant cost reductions.

But again, the key is to maintain quality while doing so. Switching to a lower-cost supplier only makes sense if service levels and output remain consistent. Vendor scorecards and regular reviews can help ensure standards stay high while you pursue cost savings in the background.

Avoiding False Economies

It’s worth noting that not all cost savings are created equal. Sometimes, a cheaper solution leads to more expensive problems down the line—be it product returns, customer complaints, or internal inefficiencies. These “false economies” can do more harm than good.

This is why a long-term perspective is essential. Will this savings tactic still make sense in six months? A year? Will it scale as the company grows? Asking these questions ensures you’re not just optimizing for today, but for sustained performance and resilience.

Data-Driven Decisions for Sustainable Results

For example, if a particular product line consistently yields high return rates, it might be time to revisit the design or materials. If a certain customer segment requires extensive support, proactive onboarding tools might reduce that need. With data, you move from guesswork to precision—and the savings follow naturally.

Communication and Transparency

One often-overlooked element of any successful cost savings initiative is communication. When changes are introduced without context, employees and customers may assume the worst. But when savings are framed as part of a broader commitment to quality and sustainability, they’re more likely to be embraced and supported.

Internal transparency also helps teams understand the “why” behind new initiatives. It fosters a culture of accountability and shared ownership, where every department plays a role in identifying and implementing cost savings without undermining the customer experience.

Building a Culture of Smart Spending

Ultimately, lasting cost savings come from cultural alignment, not quick fixes. When everyone in the organization—from entry-level to executive—understands the importance of efficiency, innovation, and value-driven decision-making, the path to cost-effective quality becomes much clearer.

This doesn’t mean micromanaging every purchase. It means cultivating an environment where people are empowered to challenge outdated processes, propose smarter solutions, and take pride in doing more with less. Over time, this mindset becomes embedded—and cost savings become a natural byproduct of great execution.

Conclusion: Excellence Doesn’t Have to Be Expensive

The pursuit of cost savings doesn’t have to feel like a zero-sum game. With strategic planning, smart investments, and a relentless focus on value, organizations can unlock meaningful savings while still delivering products and services that delight their customers.

It’s not about compromise—it’s about clarity. Clarity on what matters most, where waste lives, and how to align every resource toward outcomes that matter. In that sense, cost savings become more than a financial goal. They become a philosophy—one that champions efficiency, innovation, and quality in equal measure.

Andrea Balint is a writer and researcher focused on human behavior, workplace psychology, and personal growth. Through her work at CareersMomentum, she explores how mindset, leadership, and emotional intelligence shape modern careers. With a background in communication and HR development, she transforms complex ideas into practical insights that help readers build clarity, confidence, and professional purpose.